Drones have come a long way from just flying cameras. Today’s Unmanned Aerial Vehicles (UAVs) are intelligent, modular systems that operate as full-fledged mission platforms across defense, energy, agriculture, and advanced air mobility.

What sets the newest generation of UAVs apart isn’t just flight performance; its adaptability. These platforms are built to change roles, scale capabilities, and operate autonomously in some of the most demanding environments on earth. And behind their success lies an often-overlooked enabler: the interconnect systems that bind every subsystem together.

Modularity: The New Standard for Aerial Systems

Next-gen UAVs are being designed around modular payload architectures. Rather than building a new airframe for every mission type, operators can now swap payloads on demand:

- Need ISR? Mount a sensor module.

- Running a communications relay? Swap in a different payload; no redesign required.

This plug-and-play approach drastically reduces deployment times and engineering overhead. More importantly, it gives operators flexibility to reconfigure platforms for evolving mission needs in minutes, not months.

Smarter Drones, Working in Swarms

Beyond modularity, UAVs are getting smarter and more coordinated.

AI-enabled swarm technologies allow groups of drones to autonomously patrol borders, scan disaster zones, or perform cooperative search-and-rescue. Onboard edge processors handle decision-making in real time, reducing the need for ground control.

All of these place greater demands on interconnect systems: more bandwidth, lower latency, tighter EMI tolerance, and smaller, lighter cable assemblies. Getting that balance right between performance, size, and durability is what enables these missions to succeed.

Quietly Powering the Mission: A Role for Interconnect Innovation

While UAV performance often gets the headlines, there’s a quiet layer of technology underneath making it all possible.

That’s where companies like Mitas Electronics come in.

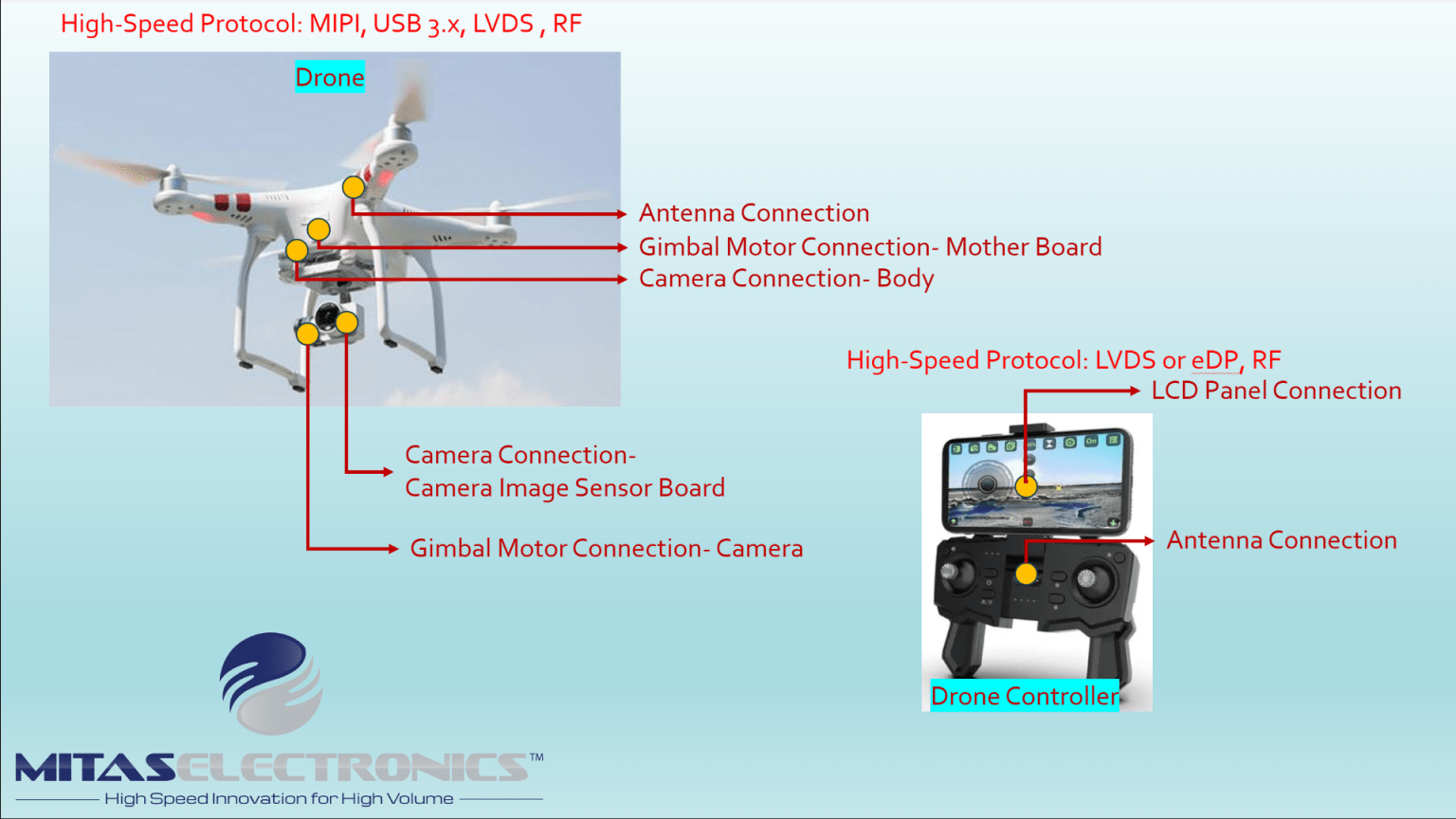

Mitas focuses on agile engineering and application-specific interconnect assemblies, the kind of work that matters when you’re flying a sensitive sensor array through high-altitude turbulence or trying to shield signal lines from interference in a dense RF environment.

Proven in Harsh Environments

The environments military UAVs operate in are anything but forgiving. Blistering desert heat, maritime salt air, high-altitude cold, and constant vibration all take a toll on electronics.

Interconnects must survive these extremes while maintaining data and power integrity. That’s why military UAV developers lean on partners who can not only prototype quickly but also engineer durability from the start.

Mitas supports these needs with U.S.-based design support and a global supply network. For developers building next-generation aerial systems, this kind of responsive engineering and manufacturing support can mean the difference between a grounded prototype and a flying platform.

Enabling the Future of Flight

From defense to energy, from agriculture to urban logistics, UAVs are changing how we operate in the world:

- In defense, they reduce risk and extend reach

- In energy, they inspect remote infrastructure with real-time data feedback

- In agriculture, they apply precision spraying and data-driven crop analysis

- In advanced air mobility, they are paving the way for autonomous logistics and delivery

Behind each of these breakthroughs is a web of electrical connections, carrying data, power, and control signals across systems. Those connections must be light, reliable, and resilient.

That’s where Mitas Electronics quietly supports the mission.

UAVs are getting faster, smarter, and more modular, but none of them work without dependable interconnects. While they may be hidden under hatches and inside enclosures, cables and connectors play a frontline role in UAV success.

Ready to take your UAV systems to the next level?

Partner with Mitas Electronics and build the interconnect foundation your mission deserves.

Let’s engineer what’s next together.