In today’s world of thinner, lighter, and more powerful laptops, performance expectations are high and the margin for error is low. As OEMs (Original Equipment Manufacturers) and ODMs (Original Design Manufacturers) continue to innovate with slimmer form factors and more complex designs, one element remains consistently overlooked, yet essential: the hinge cable assembly.

It’s easy to miss. After all, hinge cables aren’t visible to end users. But their performance directly impacts the laptop’s reliability, durability, and user experience. At Mitas Electronics, we understand this better than most and we’ve built an entire engineering approach around it.

The Engineering Challenge Inside Every Hinge

Hinge cables route critical signals between the laptop’s base and its display. These include:

- eDP and MIPI display interfaces

- USB 3.x and high-speed data lines

- Camera and touchscreen signals

- Power delivery for lighting and sensors

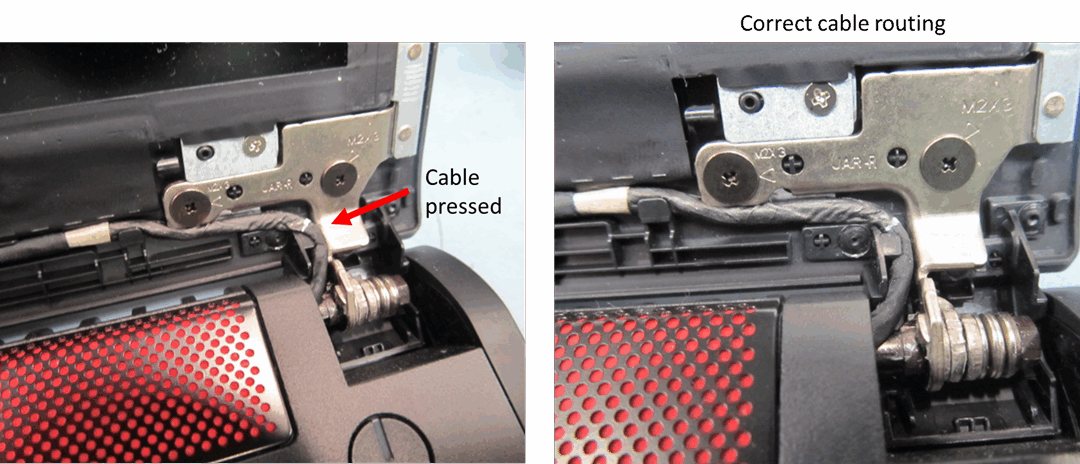

These signals must travel through a moving joint that typically allows less than 4 mm of vertical space and demands a bend radius tighter than 5 mm. Worse yet, the cable flexes every time the lid is opened or closed potentially tens of thousands of times over the product’s lifecycle.

Without careful design, this results in cable fatigue, intermittent signal issues, or outright failure.

How Mitas Electronics Solves It

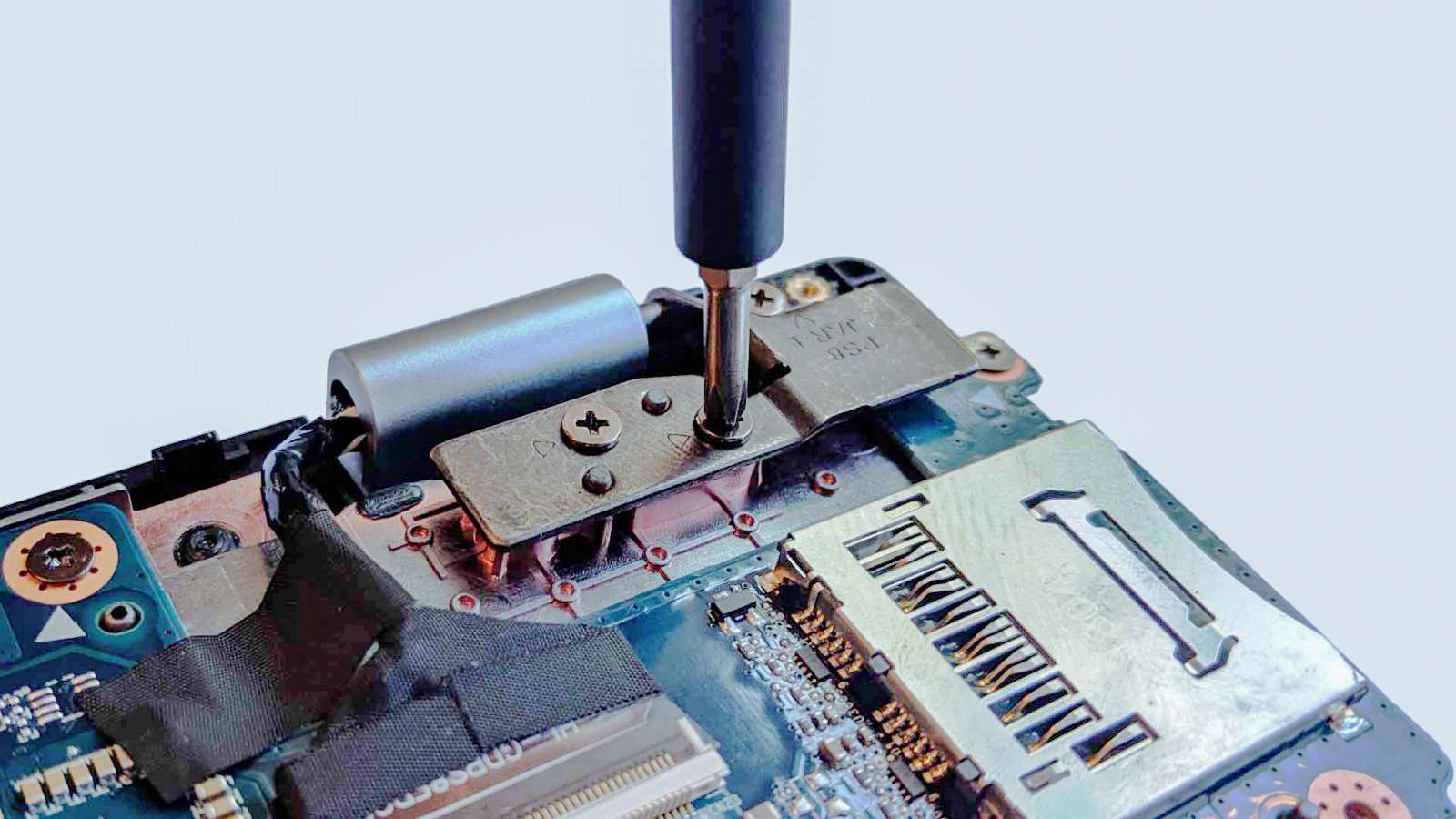

Mitas Electronics develops custom hinge cable assemblies that address the mechanical and electrical demands of this application with precision.

We start by selecting the right materials:

- Ultra-fine stranded conductors (AWG 42–34) for flexibility

- Micro-coaxial and twinaxial cables for high-speed integrity

- FFC and FPC for ultra-slim routing when profile matters most

Our assemblies incorporate EMI shielding, strain reliefs, and connector interfaces from top brands like I-PEX, JAE, and Hirose. All assemblies are designed to fit within your hinge constraints while maintaining long-term signal and structural integrity.

Each solution is validated with rigorous mechanical testing, including 20,000+ flex cycles, thermal aging, and drop simulations.

OEM & ODM Benefits

When you work with Mitas, you’re not just buying a cable, you’re getting an interconnect manufacturing partner.

We support:

- Early-stage DFM support (for cost, performance, and ease of assembly)

- Prototype builds and quick iterations

- Production scalability from pilot to mass volumes

- Fast lead times for engineering samples

This results in fewer failure points, shorter development cycles, and smoother integration into your assembly line.

Where Our Hinge Solutions Go

- Ultra-slim consumer laptops

- Detachable and 2-in-1 convertibles

- Rugged field laptops and tablets

- Medical and industrial portable devices

Wherever reliability meets motion, cable that route to hinges matter. And we deliver solutions that last.

Let’s Build Better, Together

The hinge may seem like a small part of the laptop but it’s a big test for the interconnect system. At Mitas Electronics, we help OEMs meet that test with smarter, more reliable cable assemblies designed to move with confidence.

Need support with a hinge cable project?

Reach out to our engineering visit

🌐 www.mitaselectronics.com