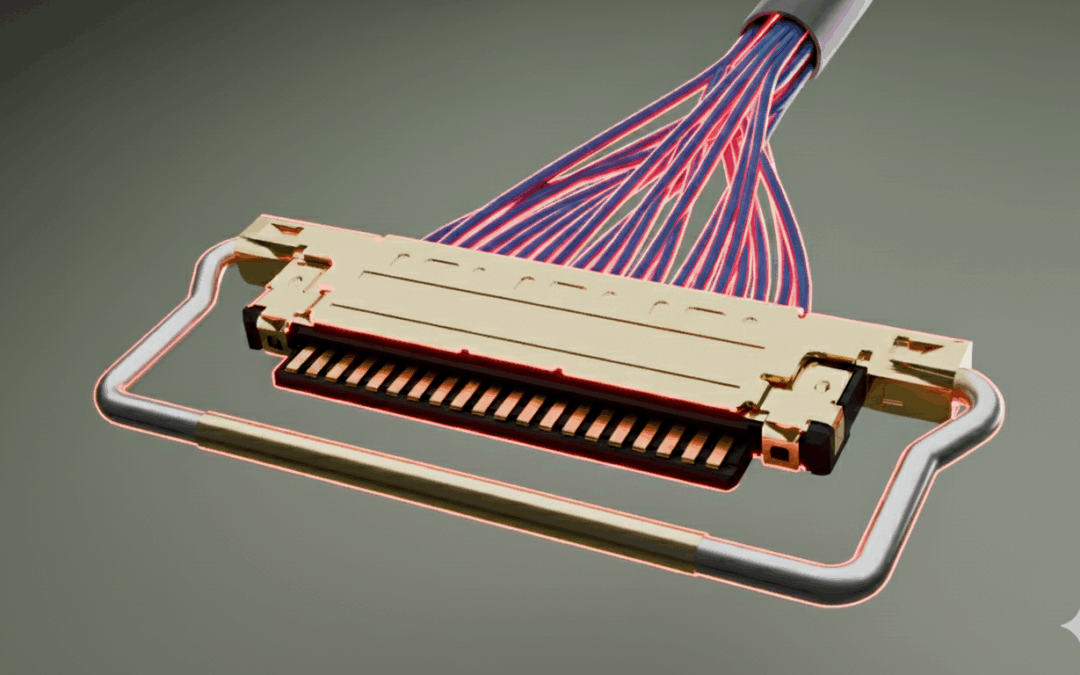

In the world of electrical systems, wire bundles are everywhere. From the complex wiring looms in an aircraft’s avionics bay to the simple grouped cables in a household electrical junction box, wire bundles play a crucial role in transmitting power and signals. However, when multiple wires are bundled together, a phenomenon known as current derating becomes a key consideration. At Mitas Electronics, we understand the importance of this concept, and in this blog, we’ll explore everything you need to know about wire bundle current derating.

What is Current Derating?

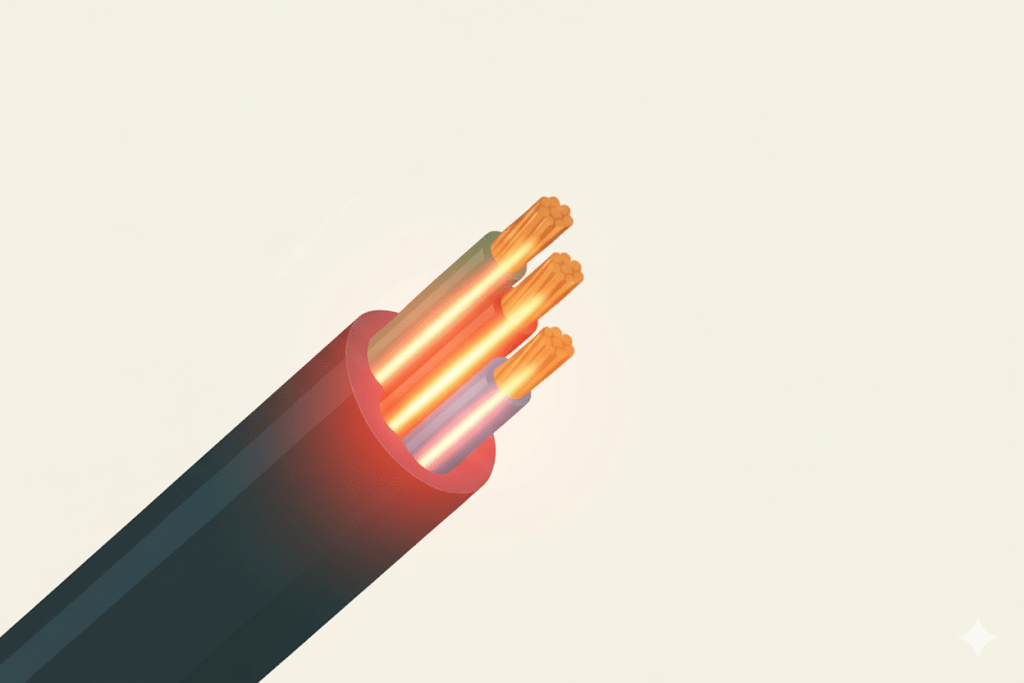

Derating, in the context of electrical systems, is the practice of operating a component (in this case, wires) at less than its maximum rated capacity. When it comes to wire bundles, current derating specifically refers to reducing the amount of current that each wire in the bundle can safely carry. This is essential because as current flows through a wire, it generates heat due to the wire’s resistance. In a bundle, the close proximity of wires makes it more difficult for this heat to dissipate, leading to a build-up of temperature. If the wires are allowed to carry their full-rated current, the elevated temperature can cause the insulation to degrade, potentially leading to short circuits, fires, or other electrical failures.

Factors Affecting Wire Bundle Current Derating

Number of Conductors in the Bundle

The more wires there are in a bundle, the more heat is generated overall, and the harder it is for the heat to escape. Industry standards provide derating factors based on the number of current-carrying conductors in a bundle. For example, in many cases, if you have 2 – 5 current-carrying conductors in a bundle, the derating factor might be 80% of the wire’s normal ampacity (the amount of current it can carry under standard conditions). If the number of conductors increases to 6 – 15, the derating factor could drop to 70%, and for 16 – 30 conductors, it may be as low as 50%. As the number of conductors in the bundle continues to grow, the derating factor decreases further, highlighting the significant impact of bundle size on current-carrying capacity.

Ambient Temperature

The temperature of the surrounding environment, known as the ambient temperature, also plays a major role in wire bundle current derating. Higher ambient temperatures mean that the wires are already starting at a higher temperature, and the heat generated by the current flowing through them has less of a temperature differential to dissipate into the environment. As a result, the wires heat up more quickly. For instance, if a wire has a normal ampacity at an ambient temperature of 30°C, at 40°C, its ampacity might be reduced to 90% of the original value. At 50°C, it could be down to 76%, and at 60°C, 60% of the original ampacity, depending on the wire type and insulation characteristics.

Insulation Type and Quality

-

The type and quality of the insulation around the wires in a bundle are also important. Different insulation materials have different thermal properties. Some materials are better at resisting heat and maintaining their integrity at higher temperatures, while others may soften or degrade more easily. For example, Teflon or FEP-insulated wires, which are commonly used in high-temperature applications, can withstand higher temperatures before their performance is affected compared to standard PVC insulation. Wires with high-quality, heat-resistant insulation can often carry more current in a bundle compared to those with lower-quality insulation, but they still require derating based on the other factors like the number of conductors and ambient temperature.

Wiring Configuration and Ventilation

-

The way the wires are configured within the bundle and the availability of ventilation around the bundle can impact current derating. If the wires are tightly packed together with little space for air circulation, heat will be trapped, leading to a higher temperature rise and more significant derating. On the other hand, if the wires are arranged in a way that allows for good ventilation, such as being spaced out or having air gaps between groups of wires, the heat can dissipate more effectively, and the derating factor may be less severe. In some industrial applications, wire trays or conduits are designed with ventilation features to help manage the heat in wire bundles.

How to Calculate Wire Bundle Current Derating

Calculating wire bundle current derating involves a few steps. First, you need to determine the base ampacity of the individual wire. This information can usually be found in the wire manufacturer’s datasheet and is based on the wire gauge and insulation type. For example, a 34-gauge copper wire with PFA insulation type have a base ampacity of 1.1 amps.

Next, consider the derating factors. If you have a bundle of 8 wires (so you need to apply a bundling derating factor), and the ambient temperature is 40°C (requiring an ambient temperature derating factor), you would look up the appropriate derating percentages in the relevant electrical code tables or industry standards. Let’s say the bundling derating factor for 8 wires is 70% and the ambient temperature derating factor for 40°C is 90%.

To calculate the derated ampacity, you first apply the ambient temperature derating: 1.1 amps x 0.9 =0.99 amps. Then, you apply the bundling derating to this new value: 0.99 amps x 0.7 = 0.693 amps. So, in this example, the wire in the bundle can safely carry 00.693 amps under these conditions.

Importance of Proper Wire Bundle Current Derating

Proper wire bundle current derating is crucial for several reasons. Firstly, it ensures the safety of the electrical system. By preventing wires from overheating, the risk of electrical fires and other hazards is significantly reduced. In industrial settings, where large amounts of electrical power are used, this can be a matter of life and death. Secondly, it helps to extend the lifespan of the wires and the overall electrical system. When wires are not overloaded with excessive current, their insulation remains in better condition, and they are less likely to fail prematurely. This can save on maintenance and replacement costs in the long run. Finally, in many applications, compliance with electrical codes and standards is mandatory, and proper wire bundle current derating is often a requirement. Failure to meet these standards can result in fines, delays in project completion, or even the shutdown of an operation.

Mitas Electronics and Wire Bundle Current Derating

At Mitas Electronics, we are well-versed in the intricacies of wire bundle current derating. Our team of experts understands how to select the right wires, calculate derating accurately, and design wiring systems that are safe, reliable, and compliant. We offer a wide range of wire and cable products suitable for various applications, taking into account factors such as temperature ratings, insulation types, and current-carrying capacities. Whether you are working on a small-scale electronics project or a large industrial installation, we can provide you with the guidance and products you need to ensure proper wire bundle current derating and the successful operation of your electrical system.

In conclusion, wire bundle current derating is a fundamental concept in electrical engineering that cannot be overlooked. By understanding the factors involved, how to calculate derating, and its importance, you can design and maintain electrical systems that are safe, efficient, and long-lasting. And with the support of companies like Mitas Electronics, you have the resources to make the right choices for your wiring needs.